What is Bolt Tension Monitoring?

What is Bolt Tension?

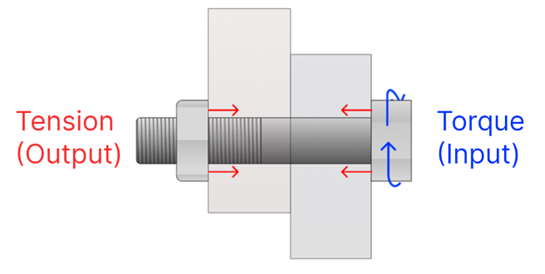

Bolt tension refers to the force or stress applied to a bolt to secure two or more components together. When a bolt is tightened, it elongates and creates tension within the bolt and the connected components. This tension generates a clamping force, also known as the preload, which holds the components in place. It helps to think of a bolt as a very stiff spring, that when stretched out acts to pull the two parts together.

Why is Bolt Tension important?

An appropriate level of tension is crucial for ensuring the integrity and reliability of the bolted joint. Sufficient tension is necessary to prevent the connection from loosening due to external forces, vibrations, or thermal expansion/contraction. However, that doesn’t mean you should just drive the bolts to max torque every time; excessive tension can lead to bolt failure or damage to the components, so it’s very important to not over-tighten bolts.

Are tension and torque equivalent?

No; one of the easiest ways to think about the relationship between torque and tension is in terms of applied force and resultant force. Torque is the twisting force applied to the bolt or fastener, tension is the resultant force of this tightening procedure. As a result of the frictional forces that act on the bolt’s surface, not all input torque is converted to resultant bolt tension.

How do technicians ensure target tension?

Bolt tension is typically achieved by torqueing the bolt or by applying a specified preload using a calibrated tensioning device. The tension is often expressed as a percentage of the bolt’s yield strength or as a specific load value, with most applications aiming for 75-90% of the bolt’s yield strength, a point known as the ‘proof load’. The most common bolt tensioning device on the market is the torque wrench, but there are also simple wrenches, hydraulic drivers, load-sensing bolts and ultrasonic measurement devices often used in combination to achieve the proper tension.

What are the limitations of torque wrenches?

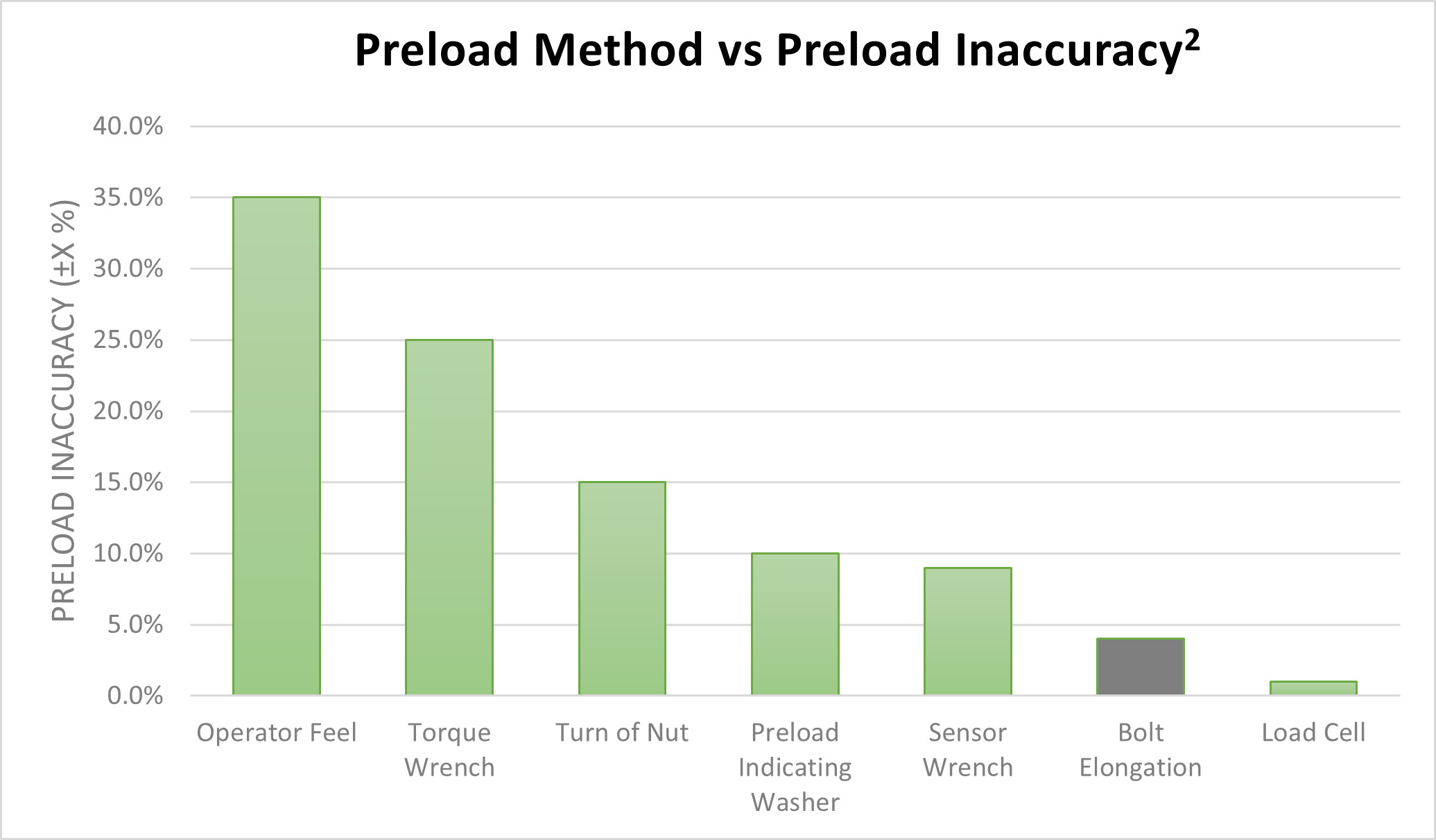

From an accuracy standpoint, if reliably calibrated and of sufficiently high-quality, a torque wrench user can expect a preload inaccuracy of ±25% . The main source of this inaccuracy comes from the difficulty of measuring the force of friction that opposes the bolt’s rotation.

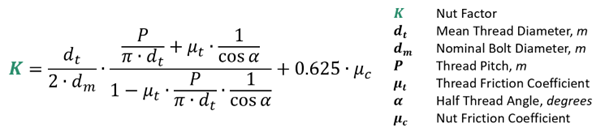

Frictional forces are difficult to measure because many factors affect their magnitude. The equation F =T/kD is often used to estimate how much torque is required to reach a specific preload figure, with F being the load, T being the torque, D being the diameter of the bolt and k being the ‘nut factor’ that encompasses the frictional resistance. Textbooks often give a standard value of k as 0.2, but it varies greatly depending on the environmental circumstances. The equation below describes how k is calculated: 1 Fastener Standards. 5th ed., Industrial Fasteners Institute, Cleveland, OH, 1970. 2 MIL-HDBK-60, “Threaded Fasteners - Tightening to Proper Tension,” 1990.

What is Ultrasonic Bolt Tension Monitoring?

Ultrasonic bolt tension monitoring is a non-destructive testing technique used to measure the length of a bolt under tension, and from this value of elongation allow the operator to derive values for tension, stress, strain. This approach avoids the difficulty associated with accurately assessing the magnitude of frictional forces.

Dakota NDT’s Bolt Tension Monitors work very much like traditional ultrasonic thickness gauges, but with additional bolt-centric features and tools that allow them to achieve incredible accuracy. An ultrasonic transducer is fixed to one end of the bolt, which sends an ultrasonic pulse into it. The pulse reflects off the other side of the bolt and returns to the transducer, allowing the overall length to be calculated from the Time-of-Flight (TOF) between pulse and echo.

How does a Dakota Bolt Tension Monitor address the limitations of torque wrenches?

Friction-Independent Measurement: Bolt Tension Monitors directly measure the elongation of the bolt, allowing for accurate tension assessment without the need to explicitly consider or address frictional effects. This friction-independent measurement method simplifies the tensioning process and minimizes the main source of tensioning error.

Enhanced Accuracy: Dakota NDT’s decades of technical expertise with ultrasonic thickness gauges allows our Bolt Tension Monitors to achieve accuracy levels as fine as ±0.1µm (±0.01 thou), providing a very precise means of calculating the bolt tension.

Automatic Temperature Compensation: Bolt tension is sensitive to temperature changes, as it affects the thermal expansion and contraction of the components. Unlike torque wrenches Dakota Bolt Tension systems feature automatic temperature compensation functionality. This allows the gauge to adjust the measured elongation to account for temperature fluctuations, ensuring accurate and consistent tension measurements across different operating conditions.

Traceability and Auditability: Dakota's Bolt Tension systems offer a significantly higher level of traceability and auditability compared to torque wrenches. These systems often incorporate advanced data logging capabilities, recording precise measurements, environmental conditions, and other relevant parameters. This detailed data can be used for traceability purposes, enabling the tracking of tension values over time and ensuring compliance with quality standards. Moreover, the recorded data enhances the auditability of the bolted connections, facilitating analysis, verification, and validation of the tensioning process.

What Bolt Tension Monitors do Dakota NDT provide?

The Dakota BT-1DL Bolt Tension Monitor

The Dakota BT-1DL Bolt Tension Monitor is an entry-level tension monitor that combines simplicity and functionality. It is a lightweight and portable device, weighing only 380g with batteries.

Despite its compact size, the Dakota BT-1DL Bolt Tension Monitor is compatible with a wide range of bolt sizes, ranging from 1 inch up to 50 feet (25.4mm – 15.2m). This versatility makes it suitable for various industrial and construction settings.

The monitor features a long battery life of up to 35 hours, ensuring extended operation without frequent battery replacement. Additionally, the Dakota BT-1DL Bolt Tension Monitor boasts 4GB of internal memory for storing measurement data, allowing for convenient data retrieval and analysis.

The Dakota BT-2DL Bolt Tension Monitor

The Dakota BT-2DL Bolt Tension Monitor is a benchtop tension monitor that offers enhanced features and capabilities. It comes equipped with a full-colour VGA display operating at a refresh rate of 60Hz. This display provides a clear and detailed interface for visualizing tension measurements and system parameters.

The Dakota BT-2DL Bolt Tension Monitor supports multiple measurement modes, including Echo-Echo and Echo-Echo-Verify, allowing for more versatility on difficult bolt types. With a wide compatibility range, it can handle bolts ranging from 1/2 inch to 100 feet (15mm – 30.4m).

The Dakota BT-2DL Bolt Tension Monitor features an additional 64GB external SD card storage, ensuring ample space for storing measurement data for later analysis and reporting.

Summary:

Our bolt tension monitor line-up includes the BT-1DL and BT-2DL. Each model offers specific features and advantages, catering to different user requirements. Whether you need a lightweight and portable solution, a benchtop monitor with advanced display capabilities, or a remote monitoring system for difficult installations, our range of bolt tension monitors is designed to provide accurate, reliable, and convenient tension measurement solutions.