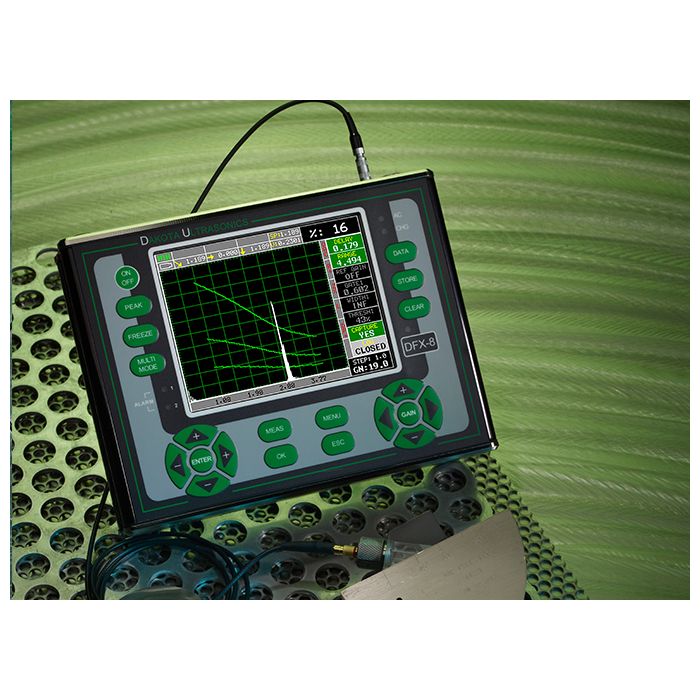

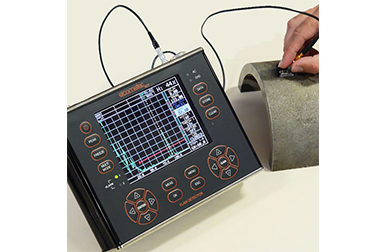

Dakota FX80 Benchtop Flaw Detector (DFX-8)

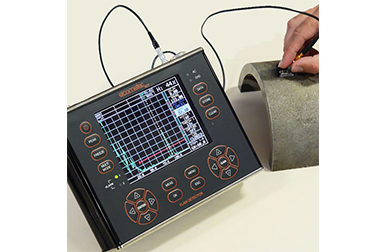

The Dakota FX80 Bench Top Flaw Detector range combines state-of-the-art flaw detection with advanced material thickness capabilities.

- Summary

-

Summary

-

Designed for use in the laboratory these gauges are the tool you need for all your flaw detecting needs.

The Dakota FX80 Bench Top Ultrasonic Flaw Detector is available in two models: Dakota FX80-DL Bench Top Flaw Detector and Dakota FX81-DL Bench Top Flaw Detector.

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

Within the grid batching of the Dakota FX80 Flaw Detector the user has the capability to enter 'OBSTRUCT' on to the grid for easy identification of inaccessible locations to measure.

The Dakota FX80 Ultrasonic Flaw Detector has a 6Gb internal memory and an external SD slot which allows up to 64Gb with full data logging via RS232 data output to DakMaster™ data management software.

Transducer Options

A wide range of Shear Wave Transducers, Single Element Transducers and Transducer Wedges available

-

- Key Features

-

Key Features

Dakota FX80 Benchtop Flaw Detector (DFX-8)

Features:

- Blanview sunlight readable QVGA TFT colour display

- Sizing Toolkits: DAC, AWS, TCG, DGS

- Pulse Repetition Frequency: 8 to 333 Hz, adjustable

- Screen Refresh Rate: 60Hz

- Detection: Z-Cross, Flank & Peak

- Automatic: probe zero, probe recognition, and temperature compensation

- Measurement: Variety of modes to address a number of applications

- Large data storage: 6Gb internal & up to 64Gb external SD slot

- Multiple formats: Alpha numeric grid and sequential with auto identifier

- Up to 12 hours of battery life

- Download to DakMaster™ data management software

-

- Product Features

-

Product FeaturesDakota FX80 Benchtop Flaw Detector (DFX-8)

Material Thickness Features Model FX80-DL & FX81-DL Display Mode Material thickness digits display B-Scan cross sectional display B-Scan with digits display Scan bar display Coating thickness display A-Scan display + Rectified, - Rectified, Full Waveform (RF)Flaw Detection Modes TRIG, DAC, AWS, TCG, AVG/DGSMeasurement Range P-E:

Pulse Echo (Dual Contact) : 0.630 - 2,440mm (0.025 – 96”)

Pulse Echo (Single Contact) : 1.000 - 30,480mm (0.040 - 1200”)

E-E:

Echo Echo ThruPaint™ (Dual Contact): 1.270 - 102mm (0.050 - 4”)

Echo Echo (single delay line) : 0.178 - 25.4mm (0.007 - 1”)

Echo Echo (single contact) : 1.000 - 3,050mm (0.040 - 120”)

Echo Echo Verify (EEV): 1.270 - 25.4mm (0.050 - 1”)

PETP:

Pulse Echo Temp Comp: 0.630 - 2,440mm (0.025 – 96”)

CT:

Coating Thickness: 0.013 - 2.54mm (0.001 - 0.1”)

PECT:

Pulse Echo Coating Thickness (Coating) 0.010 - 2.54mm (0.001 - 0.1”)

Pulse Echo Coating Thickness (Substr.) 0.630 - 2,440mm (0.025 – 96”)Resolution 0.01mm (0.001”), 0.001mm (0.0001”) selectableMeasurement Rate (Thickness Mode) Manual 4 readings per secondScan Mode 32 readings per secondScan bar display 6 readings per secondHigh Speed Scan Mode Differential Mode Limit alarm mode B-Scan display speed adjustable display speedCalibration setups 64 user-definable setups transferrable to and from a PC archiveGates 2 (flaw) and 3 (thickness) adjustable gates: start, stop, width & thresholdDamping 50, 75, 100, 300, 600, & 1500 ohmsPulser type FX80-DL: Two adjustable square wave pulsers, 100 - 200v

FX81-DL:Two tone burst pulsers, 100 - 400vGain Manual, automatic gain control (AGC) with 110dB range with 0.2dB resolutionTiming Precision TCXO timing with single shot 100 MHz 8 bit ultra-low power digitizerMemory and Data Logging 4GB internal memory

Sequential and grid logging

Alpha numeric batch identification

OBSTRUCT indicates inaccessible locations

Bitmap graphic captureData Output USB-CCalibration Options single, two point, velocity, material typeTransducer recognition AutomaticV-path / dual path error correction AutomaticProbe Zero AutomaticAutomatic Calibration Longitudinal (straight), or Shear (angle)Flaw Detection Product Features Probe Types Single Contact, Dual, Delay & AngleMaterial Velocity Table Contains longitudinal and shear velocities for a variety of material typesTRIG Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducersDAC Up to 8 points may be entered and used to digitally draw a DAC curve. Reference -2, -6, -10, (-6/-12), (-6/-14), (-2/-6/-10) dB. Amplitude displayed in %DAC, dB, or %FSHAWS Automatic defect sizing in accordance with AWS D1.1 structural welding code.AVG/DGS Automatic defect sizing using probe data. Stores up to 64 custom setupsTCG Time corrected gain. 50 dB dynamic range, 20 dB per microsecond, up to 8 points for curve definitionDetection Modes Zero Crossing, Flank and PeakDisplay Freeze Hold current waveform on screenPeak Memory Captures peak signal amplitudePRF 8 to 2000Hz in selectable steps (8, 16, 32, 66, 125, 250, 333, 1000, 2000Hz)Skip Bar Displays skip legs in the waveform areaPulse Width 40 to 400 ns. Selectable step options 40, 80 & 400 ns (labeled spike, thin & wide)Frequency Bands FX80-DL & FX81-DL: Broadband 1.8 - 19MHz (-3dB)

FX81-DL: Six narrow bands at 0.5MHz, 1MHz, 2MHz, 5MHz, 10MHz, 15MHz.Horizontal Linearity +/- 0.4% FSWVertical Linearity +/- 1% FSHAmplifier Linearity +/- 1 dBAmplitude Measurement 0 to 100% FSH, with 1% resolutionDelay 0 - 999in (25,375mm) at steel velocityDisplay Blanview sunlight readable QVGA TFT colour display. 115.2 x 86.4mm (4.54 x 3.40 inches) viewable screenDisplay Refresh Rate 60HzUnits (selectable) mm or inchesBacklight adjustable brightnessRepeatability / Stability Indicator Low Battery Indicator Battery Save Mode Auto

-

- Technical Information

-

Technical SpecificationDakota FX80 Benchtop Flaw Detector (DFX-8)

Part Number Description Certificate Z-250-0001 Dakota FX80-DL Benchtop Flaw Detector (DFX-8)

Z-251-0001 Dakota FX81-DL Benchtop Flaw Detector (DFX-8+)

Operating Temperature -10 to 60ºC (14 to 140ºF) Power Supply 6 x AA batteries and via USB Battery Life2 Alkaline (12hrs), Nicad (5hrs), and NI-MH (12hrs) Gauge Weight 2.04kg (4.5lbs) - including batteries Gauge Dimensions 216.0 x 165.0 x 70.0mm (8.5 x 6.5 x 2.5 inches) Packing List Unit, Selectable Transducer, Couplant, Manual, Power Cable, Plastic Carrying Case, Certificate of Calibration and AA Batteries. PC Software and Data Transfer Cable ● Certificate of Calibration supplied as standard

-

- Standards

-

StandardsDakota FX80 Benchtop Flaw Detector (DFX-8)

Thickness Gauge: Factory calibration traceable to NIST & MIL-STD-45662A.

Flaw Detector: EN12668-1 compliant.

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersDakota FX80 Benchtop Flaw Detector (DFX-8)No data found!!

-

Dakota FX80-DL Benchtop Flaw Detector (DFX-8)

Dakota FX80-DL Benchtop Flaw Detector (DFX-8)- Part Number : Z-250-0001

-

Dakota FX81-DL Benchtop Flaw Detector (DFX-8+)

Dakota FX81-DL Benchtop Flaw Detector (DFX-8+)- Part Number : Z-251-0001

-

- Home

- Flaw Detectors

- Dakota FX80 Benchtop Flaw Detector (DFX-8)

Dakota FX80 Benchtop Flaw Detector (DFX-8)

The Dakota FX80 Bench Top Flaw Detector range combines state-of-the-art flaw detection with advanced material thickness capabilities.

Summary

Dakota FX80 Benchtop Flaw Detector (DFX-8)

Designed for use in the laboratory these gauges are the tool you need for all your flaw detecting needs.

The Dakota FX80 Bench Top Ultrasonic Flaw Detector is available in two models: Dakota FX80-DL Bench Top Flaw Detector and Dakota FX81-DL Bench Top Flaw Detector.

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

Within the grid batching of the Dakota FX80 Flaw Detector the user has the capability to enter 'OBSTRUCT' on to the grid for easy identification of inaccessible locations to measure.

The Dakota FX80 Ultrasonic Flaw Detector has a 6Gb internal memory and an external SD slot which allows up to 64Gb with full data logging via RS232 data output to DakMaster™ data management software.

Transducer Options

A wide range of Shear Wave Transducers, Single Element Transducers and Transducer Wedges available

Key Features

Dakota FX80 Benchtop Flaw Detector (DFX-8)

Features:

- Blanview sunlight readable QVGA TFT colour display

- Sizing Toolkits: DAC, AWS, TCG, DGS

- Pulse Repetition Frequency: 8 to 333 Hz, adjustable

- Screen Refresh Rate: 60Hz

- Detection: Z-Cross, Flank & Peak

- Automatic: probe zero, probe recognition, and temperature compensation

- Measurement: Variety of modes to address a number of applications

- Large data storage: 6Gb internal & up to 64Gb external SD slot

- Multiple formats: Alpha numeric grid and sequential with auto identifier

- Up to 12 hours of battery life

- Download to DakMaster™ data management software

Product FeaturesDakota FX80 Benchtop Flaw Detector (DFX-8)Material Thickness Features Model FX80-DL & FX81-DL Display Mode Material thickness digits display B-Scan cross sectional display B-Scan with digits display Scan bar display Coating thickness display A-Scan display + Rectified, - Rectified, Full Waveform (RF)Flaw Detection Modes TRIG, DAC, AWS, TCG, AVG/DGSMeasurement Range P-E:

Pulse Echo (Dual Contact) : 0.630 - 2,440mm (0.025 – 96”)

Pulse Echo (Single Contact) : 1.000 - 30,480mm (0.040 - 1200”)

E-E:

Echo Echo ThruPaint™ (Dual Contact): 1.270 - 102mm (0.050 - 4”)

Echo Echo (single delay line) : 0.178 - 25.4mm (0.007 - 1”)

Echo Echo (single contact) : 1.000 - 3,050mm (0.040 - 120”)

Echo Echo Verify (EEV): 1.270 - 25.4mm (0.050 - 1”)

PETP:

Pulse Echo Temp Comp: 0.630 - 2,440mm (0.025 – 96”)

CT:

Coating Thickness: 0.013 - 2.54mm (0.001 - 0.1”)

PECT:

Pulse Echo Coating Thickness (Coating) 0.010 - 2.54mm (0.001 - 0.1”)

Pulse Echo Coating Thickness (Substr.) 0.630 - 2,440mm (0.025 – 96”)Resolution 0.01mm (0.001”), 0.001mm (0.0001”) selectableMeasurement Rate (Thickness Mode) Manual 4 readings per secondScan Mode 32 readings per secondScan bar display 6 readings per secondHigh Speed Scan Mode Differential Mode Limit alarm mode B-Scan display speed adjustable display speedCalibration setups 64 user-definable setups transferrable to and from a PC archiveGates 2 (flaw) and 3 (thickness) adjustable gates: start, stop, width & thresholdDamping 50, 75, 100, 300, 600, & 1500 ohmsPulser type FX80-DL: Two adjustable square wave pulsers, 100 - 200v

FX81-DL:Two tone burst pulsers, 100 - 400vGain Manual, automatic gain control (AGC) with 110dB range with 0.2dB resolutionTiming Precision TCXO timing with single shot 100 MHz 8 bit ultra-low power digitizerMemory and Data Logging 4GB internal memory

Sequential and grid logging

Alpha numeric batch identification

OBSTRUCT indicates inaccessible locations

Bitmap graphic captureData Output USB-CCalibration Options single, two point, velocity, material typeTransducer recognition AutomaticV-path / dual path error correction AutomaticProbe Zero AutomaticAutomatic Calibration Longitudinal (straight), or Shear (angle)Flaw Detection Product Features Probe Types Single Contact, Dual, Delay & AngleMaterial Velocity Table Contains longitudinal and shear velocities for a variety of material typesTRIG Trigonometric display of beam path, depth, surface distance, and curved surface correction. Used with angle beam transducersDAC Up to 8 points may be entered and used to digitally draw a DAC curve. Reference -2, -6, -10, (-6/-12), (-6/-14), (-2/-6/-10) dB. Amplitude displayed in %DAC, dB, or %FSHAWS Automatic defect sizing in accordance with AWS D1.1 structural welding code.AVG/DGS Automatic defect sizing using probe data. Stores up to 64 custom setupsTCG Time corrected gain. 50 dB dynamic range, 20 dB per microsecond, up to 8 points for curve definitionDetection Modes Zero Crossing, Flank and PeakDisplay Freeze Hold current waveform on screenPeak Memory Captures peak signal amplitudePRF 8 to 2000Hz in selectable steps (8, 16, 32, 66, 125, 250, 333, 1000, 2000Hz)Skip Bar Displays skip legs in the waveform areaPulse Width 40 to 400 ns. Selectable step options 40, 80 & 400 ns (labeled spike, thin & wide)Frequency Bands FX80-DL & FX81-DL: Broadband 1.8 - 19MHz (-3dB)

FX81-DL: Six narrow bands at 0.5MHz, 1MHz, 2MHz, 5MHz, 10MHz, 15MHz.Horizontal Linearity +/- 0.4% FSWVertical Linearity +/- 1% FSHAmplifier Linearity +/- 1 dBAmplitude Measurement 0 to 100% FSH, with 1% resolutionDelay 0 - 999in (25,375mm) at steel velocityDisplay Blanview sunlight readable QVGA TFT colour display. 115.2 x 86.4mm (4.54 x 3.40 inches) viewable screenDisplay Refresh Rate 60HzUnits (selectable) mm or inchesBacklight adjustable brightnessRepeatability / Stability Indicator Low Battery Indicator Battery Save Mode AutoTechnical SpecificationDakota FX80 Benchtop Flaw Detector (DFX-8)Part Number Description Certificate Z-250-0001 Dakota FX80-DL Benchtop Flaw Detector (DFX-8)

Z-251-0001 Dakota FX81-DL Benchtop Flaw Detector (DFX-8+)

Operating Temperature -10 to 60ºC (14 to 140ºF) Power Supply 6 x AA batteries and via USB Battery Life2 Alkaline (12hrs), Nicad (5hrs), and NI-MH (12hrs) Gauge Weight 2.04kg (4.5lbs) - including batteries Gauge Dimensions 216.0 x 165.0 x 70.0mm (8.5 x 6.5 x 2.5 inches) Packing List Unit, Selectable Transducer, Couplant, Manual, Power Cable, Plastic Carrying Case, Certificate of Calibration and AA Batteries. PC Software and Data Transfer Cable ● Certificate of Calibration supplied as standardStandardsDakota FX80 Benchtop Flaw Detector (DFX-8)Thickness Gauge: Factory calibration traceable to NIST & MIL-STD-45662A.

Flaw Detector: EN12668-1 compliant.

- Part Numbers

-